WS-GR glazing robot designed as intelligent manipulator for glazing by DC battery powered, all functions controlled remotely by operator including moving, lifting, extending, tilting, side-moving, and vacuum switch, multiply application offered not only for panels installation on site, but for machine feeding or handling in workshop as well All movements could be achieved by hydraulic which offered steady working continuously, Special designed side moving unit offered fine positioning during glazing Side-shift function, helped the full-loaded machine easily come through narrow aisle and gates.

The machine featured of battery powered which make sure that the machine could be applied for glass plate or curtain installation indoors or outdoors without cable connection, it has rear wheel driven part which make the machine self-moved and offered customer with flexible installation or handling method in all working positions. The machine contained hydraulic system, which provided powerful strength for lifting, extension, tilting and side moving, with sensible mechanical valve, all hydraulic cylinder moving speed could be sensible, which could be helpful for fine positioning during installation processing.

Glazing Robot Specifications:

1. Maximum load: 400kg while the arm back to end, 250kg while the arm full extended

2. Maximum lifting height: 3500mm from ground to the centre of the suction frame

3. Moving: automatically moving, speed control by manual roller sensibly

4. Lifting control: with hydraulic ram, controlled by manual mechanism valve sensibly

5. Extension control: with hydraulic ram, controlled by manual mechanism valve sensibly, maximum extension distance 650mm, maximum extension distance from the front wheel to the suction pads was 1350mm( the ram in parallel with ground)

6. Tilting control: with hydraulic ram, controlled by manual mechanism valve sensibly, the maximum tilting degree near to 135 degree

7. Rotation control: By manual, with slewing bearing and spring lock for positioning for endless rotation

8. Side moving: with hydraulic ram, controlled by manual mechanism valve sensibly, 75mm for both sides, totally 150mm

9. Side turning: By manual, with a spring lock for positioning, the maximum rotation was 180 degree, 90 degree for both sides

10. self weight: about 850kg with counterweight, 530kg without counterweight

11. Overload sensor: A micro switch mounted on steering bracket, used as detecting part for overload, the extension and lifting function will be locked while the sensor activated

12. Power: DC 24V

13. Driven unit: the rear wheels driven with DC motor worked as driven unit as well as for turning

14. Wheels: 300mm*150mm *2 solid tyre in front, single wheel of 250mm in rear

15. Driven unit power: DC 24V brush-less motor, 1.2KW

16. Hydraulic station power:1.2KW

17. Battery: 12V,100A*2

18. Maximum working period: about 20 Hours

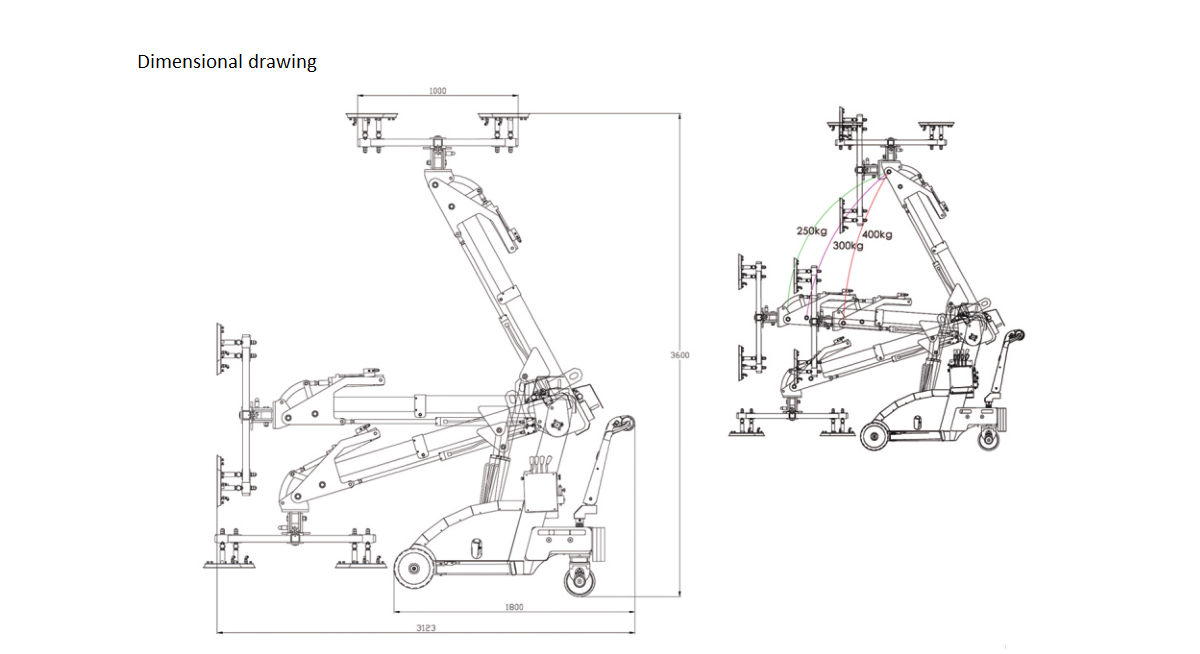

19. Dimensions: pls see the drawing

20. Charging power:110-220V

21. Charging time: about 5 hours

22. Vacuum system: Dual pump and dual system

23. the suction frame sized of 1800mm(L) and 800mm(W)

Main components in each vacuum system:

1. Vacuum Pump: CV-35, DC 24V, maximum vacuum flow 35L/minute, maximum vacuum pressure -85kpa

2. 6 of suction pads of dia.300 mm, integrated made of aluminum body with NBR, the suction pads were designed with buffer spring on upper and lower, mounted on the cross beam with retainer

3. The safety tank was designed independently, and a Non-return valve mounted safe tank to ensure a long keeping time.

4. A “Red-Green” vacuum meter mounted in front of device.

5. A Digital vacuum switch to detect the vacuum level, the switch control the vacuum starting/stopping point for power save, the preset parameter of switch was starting at -60kpa, pausing at -70kpa.

6. A of 3/2 way hand switch slide valve in each vacuum system that used for manual controlling the “Suction-Release”

7. The Red-green vacuum meter mount in front of the operator to make sure the vacuum system status in sight

8. The device has an integrated warning unit EW0 with acoustic signal. if the vacuum drops below 60% a howler starts.

9. Red-Green light mounted on electric box for showing device working status, red for alarm, and green for power through, in case the power failure or vacuum level drops down below the required level 60%, the warning system will start automatically with sound and light.

The lifter was designed for transportation or handling the materials at: Max.carrying capacity: 400kg at vertical (60% vacuum level)

WSR-600 glazing robot

We will contact you within 24 hours.